Assembly

100RPM, 40KGfcm, High Torque Motor

Our motor, 1pcs/lot 60W 40KGfcm 12V 100RPM DC geared motor High torque Metal Gear motor 550, had high speed and low torque. Our lightweight polycarbonate blocker allowed us to choose the high speed option. Since we could not afford a camera with a higher frame rate, it was imperative to have a fast motor that can keep up with the slow frame rate. Our small prototype is ideal for small children or to prove to investors we could successfully build a larger model. For future improvements, increasing the speed of the motor is important but not as essential as upgrading the camera.

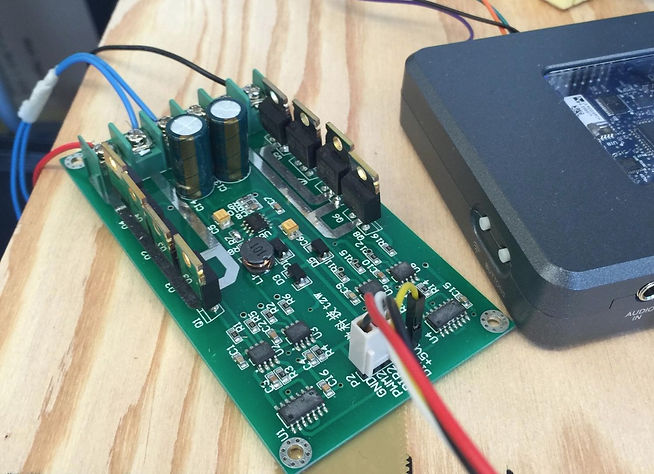

Motor Driver & NI MyRIO

RioRand® DC Smart Car PWM Dual Motor Driver Controller Module Circuit Board H-bridge MOSFET IRF3205 3-36V 15A Peak 30A was used as our main motor driver to control the motor moving the blocker. The motor driver was programmed to control the direction and the velocity of the rotation. National Instrument MyRIO was used to give the programmed PWM signal and digital output to the motor driver. MyRIO connects the LabVIEW programmed codes and the motor driver.

PlayStation3 Eye (60fps USB Camera)

PlayStation 3 Eye with 60 frames per second was used as our camera to detect and capture the position of the ball. Every frame was analyzed by the software to determine the position along the same axis that the blocker moves. We decided to choose a bright orange ball so the camera could have an easy time tracking. While testing, we realized having the camera watch from above gave us a larger area to track. Our tripod setup makes it incredibly easy to swap out the camera for one with a higher frame rate if we were to improve our product. This is incredibly important since it is the biggest factor stopping this product from being ready for use with balls moving at high speeds.

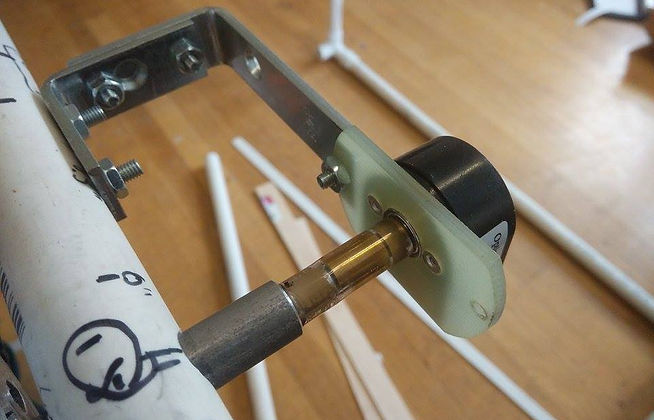

Rotary Encoder

We used a rotary encoder. Once the camera has captured the position data, it is necessary to have an encoder to track the exact position of the blocker so they align correctly. Testing and calibration was necessary to ensure the blocker moved to the correct location in front of the ball. Having an encoder also helps make sure the blocker does not try to move out of the goal area if there is a glitch in the code or hardware. Although obtaining a more precise encoder is possible, it is not as essential for improving our device as the camera or motor. Since our blocker is six inches wide and our ball is only two and a half inches in diameter, it is fine if our blocker is not exactly aligned with the ball.